- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

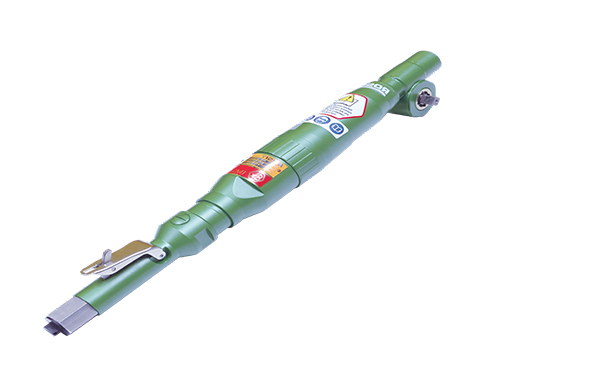

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Small ways to extend the life of using a front-mounted reaction arm wrench.Hydraulic impact wrench

source:Industry News release time:2022-05-18 Article author:yu Popular:Air band saw

Front reaction arm wrench is a very critical tool in the production process, it has the characteristics of high technology and high precision. The widespread use of this tool has made many customers aware of the need to extend hydraulic wrench life and control costs. The following is a detailed introduction to the expansion of the front-type reaction arm wrench method.

Before using the front-mounted reaction arm wrench, the operator should carefully read and understand the operation manual, and have a deep grasp of the installation, adjustment and actual operation of the hydraulic wrench, and have a certain grasp of maintenance and maintenance. Proper operation methods can prolong the service life of the front reaction arm wrench.

In the use of hydraulic oil, the high quality, cleanliness and viscosity of the hydraulic oil have a very critical impact on the stability of the hydraulic system of the front-mounted reaction arm wrench. The effect and life of the hydraulic wrench are closely related to the quality of the hydraulic oil. certain connection. Therefore, anti-wear hydraulic oil should be used as much as possible. The relative density of hydraulic oil is 0.884 g/cm2, and its various high-precision data are guaranteed. The anti-wear hydraulic oil can stabilize the hydraulic system of the hydraulic wrench, which can not only reduce the harm of high oil temperature to the viscosity of the hydraulic system, but also improve the wear resistance of the hydraulic system. Sex work has great advantages.

The oil temperature of the system software should be adjusted well, and the allowable oil temperature of A by the system software is 25℃. The working temperature is in the middle of 35 ℃-45 ℃, all the temperature exceeds 45 ℃, the system has very unfavorable conditions for the development trend. If it exceeds the required standard value, it is necessary to supervise and manage the data information of the intelligent management system, so as to check the potential safety hazards as early as possible and deal with such problems. When common faults such as abnormal operation of the company, unstable steam pressure, system structure vibration, and excessive oil temperature rise occur in the development of the technical system of hydraulic presses, the front-mounted reaction arm can only be detected by analyzing the key reasons immediately. The life span of the wrench is extended, preventing students from causing major safety accidents.

Read recommendations:

DH21-026 Pneumatic Hammer Drill

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

CB31-200 Hydraulic Band Saw

2023-06-16LW21-003 Pneumatic Winch

2023-06-29DP61-140 Emulsion Two Hand Operation Drill

2023-06-19AN32-5000 Hollow Hydraulic Wrench

2023-06-27DM11-023 Electric Magnetic Drill

2023-06-19CC22-380 Pneumatic ChainSaw (5.0KW Series)

2020-06-13DC21-400 Pneumatic Core Drill

2023-01-03RZ21-016 Pneumatic Rammer

2023-06-27AN11-3000 Electric servo CNC Torque Wrench

2023-06-27CB21-065 Pneumatic Band Saw - Aluminum Alloy Series

2021-06-07DA31-032 Hydraulic Angle Drill

2022-12-15AW22-8000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15AN71-7500 Torque Multiplier

2023-06-29AK71-130 Manual C-Hog Ring Plier (1.5 coil)

2022-12-12AN71-2000 Torque Multiplier

2023-06-29LH61-002 Emulsion Hoist

2023-06-29OF25-350 Pneumatic Fan (light/medium)

2023-06-28DP21-050 Pneumatic Two Hand Operation Drill

2020-06-13DL21-013 Pneumatic Pistol Hammer Drill

2021-06-10DB21-025 Pneumatic Rotary Drill Heavy Duty

2023-06-19AN31-120000 Hydraulic Torque Wrench

2023-06-27CR21-001 Light Pneumatic Reciprocating Saw

2021-06-07CN22-2434 Nut Cutter丨Split-type Nut Cutter

2023-06-17CB61-310丨Emulsion Band Saw

2023-06-17RH31-1550 Hydraulic Chipping Hammer

2023-06-27RH31-1250 Hydraulic Chipping Hammer

2023-06-27OW61-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10AW21-2000 Pneumatic Impact Wrench (Ex-proof Series)

2021-06-15LH22-006 Pneumatic Hoist

2023-06-29RH21-2500 Pneumatic Chipping Hammer

2021-06-15Accessories

Alloy Saw Blades

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Alloy Drill Bits丨813 Series

2023-06-06Platform Clamps丨CB863-19

2023-06-06Carbide Hollow Bits丨DM818 Series

2023-06-06Diamond Saw Chains

2020-06-13Ex-proof Sleeves KIT

2023-06-07Alloy Guide Bars丨CC814 Series

2023-06-06Cross Clamps丨CB862-22

2023-06-06Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Integrated Hollow Drill Bits丨DC81

2023-06-07Optional Accessories

2023-06-07Alloy Drill Bits丨811 Series

2023-06-06Hydraulic Pump Station

2023-06-07Water Pump

2020-06-13Alloy Saw Blades丨CR815 Series

2023-06-06Ex-proof Sleeves

2023-06-07Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06Pin

2023-06-07Shovel Blades

2023-06-07Filter assy.

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Guide Bars

2023-06-06Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Alloy Drill Bits丨812 Series

2023-06-06Diamond Saw Blades

2023-06-06Rail Clamps丨CB864-12

2023-06-06Non-metallic Alloy Saw Blades

2023-06-06

You are here: >

You are here: >