- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Instructions for safe operation of using hollow wrench.Air impact wrench

source:Industry News release time:2022-05-17 Article author:yu Popular:Air band saw

Prepare

1. Determine whether to loosen or loosen the locking screw, remove the upper and lower steering shafts, install the rotating shaft locator, drag down the reaction force locking device, install the reaction force arm in the proper position, loosen and lock the square. The working direction of the axis.

2. Connect the pump room

The high pressure inlet and outlet (a) of the pump are connected with the high pressure channel (h) of the hollow wrench, and the low voltage inlet and outlet (b) of the pump are respectively connected with the low voltage channel (r) of the hydraulic press wrench according to the hydraulic oil pipe. When connecting, insert the quick connector on the oil pipe into the top, and then tighten the fixed nut by hand.

3. Carefully check whether the high-pressure hose can be connected to a reliable one, and whether there is organic oil in the pump.

4. Connect the power cord plug of the pump.

Do not operate the diaphragm vacuum pump!

test run

◆ Place the wrench on free ground.

Turn on the main power switch of the oil pump, run the oil pump, and check whether the oil pump is working normally.

◆Press the last button on the power switch of the wired controller, then the square shaft gradually rotates, the hollow wrench stops rotating in time, and the pressure gauge rises rapidly from 0 to the set pressure; release the button, the wrench will automatically return, repeat a few times. Back, make the wrench high speed several times, observe the rotation direction of the wrench, and make sure it is loose or locked. Put the wrench on the socket specification only if there is no abnormality.

operate

◆ Adjust the pressure

Press and hold the button on the power switch of the remote control with one hand, then the square shaft gradually starts to rotate, the hollow wrench does not stop rotating in time, the pressure gauge increases from 0 speed, and the other hand adjusts and decompresses the oil pump during operation valve, adjust the needle in the pressure table to the desired asset pressure.

◆ Loosen

Adjust the pressure of the pump room to the A value, determine the rotation direction of the hollow wrench as the loose position, put the wrench on the socket specification, find the reaction force support, keep it for a long time, repeat the posture of the second and third items until it is removed. down the nut.

◆ Lock

Ⅰ. Torque setting

, the torque can be set according to the design scheme. If there is no design torque, it is recommended to set the torque according to the data information in Table 1.

Ⅱ. Pump room pressure setting

Set the pump room pressure according to the required torque and type of wrench (refer to the instructions for use)

Ⅲ. Make sure that a wrench is turned into a locked position, and the wrench can be placed on the working sleeve specification and the position of the third item in the second item is continuously performed until the nut does not move.

warn

In order to prevent accidental injury and the possibility of damaging the machine and equipment, ensure that each hollow wrench hydraulic system can bear the pressure of 70 MPa.

Can not exceed the stable load of machinery and equipment (70Mpa)

The pressure gauge in the application software indicates the working load. The pressure gauge has dialog boxes that generate conditions in the system software.

When using the photoelectric hollow wrench hydraulic press wrench, it is not allowed to exceed its allowable large working torque.

Warning: Replace damaged parts with original parts as soon as possible.

In the application, the high pressure oil pipe should be prevented from being seriously bent and coiled. Applying bent or coiled tubing can cause excessive back pressure.

Do not drop or press hanging objects on the pipe. The more serious impact is likely to cause damage to the iron wire in the oil pipeline, and the oil pipeline is likely to crack during the whole process of charging.

In order to prevent damage and damage to machinery and equipment and life safety, do not remove the rain shield on the hollow wrench body, do not modify the wrench and accessories, and do not change the valve on the hydraulic rotary joint.

Read recommendations:

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

CS21-120丨Pneumatic Handheld Circular Saw

2023-06-17LH11-005 Electric Hoist

2023-05-11LH23-1/2 Pneumatic Hoist

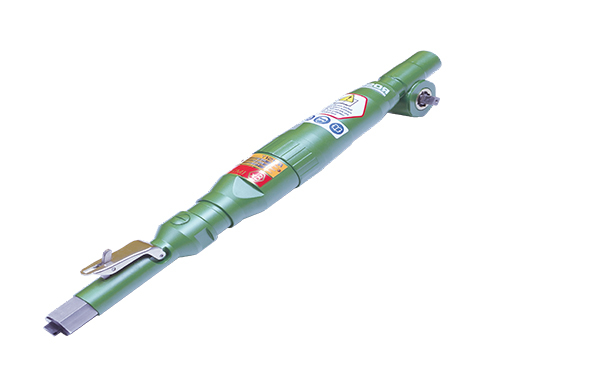

2022-12-29AN23-4500 Pneumatic Torque Wrench (Angle Shaft)

2024-03-12DB21-020 Pneumatic Rotary Drill Heavy Duty

2023-06-19DM22-023 Pneumatic Rail Drill

2023-06-19CC22-430 Pneumatic Chain Saw (5.0KW Series)

2023-06-14DM11-050 Electric Magnetic Drill

2022-12-30CB22-200 Pneumatic Band Saw - Stainless Steel Series

2023-06-16OW62-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10CB11-120 Electric Band Saw

2020-06-13CC22-530 Pneumatic Chain Saw (5.0KW Series)

2023-06-14CD22-500 Pneumatic Concrete Chainsaw (5.0KW)

2023-06-16CS31-160 Hydraulic Handheld Circular Saw

2023-06-17DM31-016 Hydraulic Magnetic Drill

2023-06-19LW21-010 Pneumatic Winch

2023-01-06CD31-500 Hydraulic Concrete Chainsaw

2023-06-16CB61-210丨Emulsion Band Saw

2023-05-18CS31-120 Hydraulic Handheld Circular Saw

2022-12-09LH22-016 Pneumatic Hoist

2023-06-29DH21-030 Pneumatic Hammer Drill

2021-06-10CN22-5060 Nut Cutter丨Split-type Nut Cutter

2022-12-12AN71-3500 Torque Multiplier

2023-06-29AN31-48000 Hydraulic Torque Wrench

2023-06-27DC21-300 Pneumatic Core Drill

2023-01-03CC21-380 Pneumatic Chainsaw (3.0 kw Series)

2022-12-08GP21-060 Pneumatic Submersible Pump

2022-12-29AN32-17000 Hollow Hydraulic Wrench

2023-06-27AN22-8000 Pneumatic Torque Wrench (straight shaft)

2023-06-27AN31-70000 Hydraulic Torque Wrench

2023-06-27Accessories

Optional Accessories

2023-06-07Water Pump

2020-06-13Carborundum saw Blades

2023-06-06Shovel Blades

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Alloy Twist Drill Bits

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Cutting Blades

2023-06-07Filter assy.

2023-06-07Carborundum Saw Chains

2023-06-06Pipe Fixed Clamps丨CB861-18

2023-06-06Core Drill Morse Taper Sleeves

2023-06-07Diamond Saw Chains丨CC813 Series

2023-06-06Alloy Saw Blades丨CR812 Series

2023-06-06Tool Bits

2023-06-07Filter assy.

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Alloy Saw Chains丨CC812/CC816 Series

2023-06-06Cross Clamps丨CB862-22

2023-06-06Pipe Fixed Clamps丨CB861-12

2023-06-06Ex-proof Sleeves KIT

2023-06-07Alloy Drill Bits丨811 Series

2023-06-06Pin

2023-06-07Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Alloy Saw Blades丨CR816 Series

2023-06-06Clamps

2023-06-06Chisels

2023-06-07Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Diamond Saw Chains

2020-06-13Abrasive Blades

2023-06-07

You are here: >

You are here: >