- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

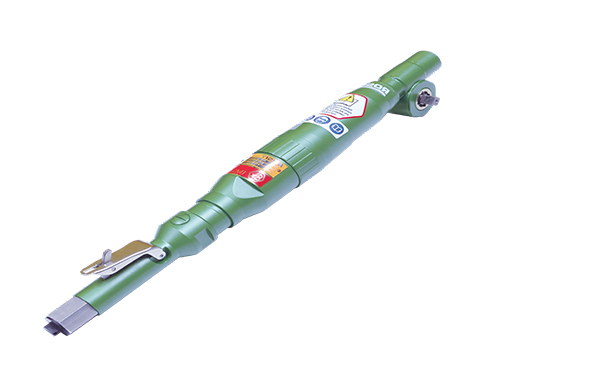

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Operation of the wrench

source:Industry News release time:2022-12-06 Article author:yu Popular:Air band saw

Pay attention to the position of the reversing switch before operation, so that you can know the direction of rotation when operating the intake valve

Be sure to ensure the compressed air entering the air motor of the wrench: clean and dry air with a maximum pressure of 6.0bar. Otherwise, it may/unavoidably lead to dangerous situations such as driveline failure, overspeed, rupture, wrong output torque, etc.

Make sure all hoses and other connections are correctly sized and securely installed; do not use damaged, worn or aged air hoses and other connections; it is recommended that an emergency shut-off valve be installed on the air supply line and that others Find out where it is installed.

Before operating the machine, be sure to check that there is enough lubricating oil in the oil cup. Lack or no lubrication will accelerate air motor blade wear, resulting in reduced tool performance and increased maintenance.

The body posture must be balanced and stable, and the tool should not be operated too much. When turning on and operating the tool, prevent and be alert to sudden changes in torque and force in motion.

In the event of a hose failure or broken connection, install an appropriately sized air safety device upstream of the hose and use a stabilizer through any hose connection to prevent the hose from wobbling without shutting off the inside of the hose.

This tool is a torque tool with a reaction arm. The huge torque generated by the machine is absorbed by the reaction arm.

Therefore, it is necessary to find a supporting point of sufficient strength for the reaction arm during operation. In view of safety considerations, when the machine is working, be sure to stay away from the working range of the reaction arm, otherwise, it may/unavoidably cause huge personal injury.

(Q)PTW series pneumatic torque wrench achieves precise torque control by adjusting the mechanical gear, air source processing components, and power management system. The operations are as follows:

Mechanical gear: check the torque comparison table, and adjust the shift knob to 1st or 2nd gear.

Adjust the air supply pressure to the required pressure as follows.

Lift the adjusting nut up and turn clockwise to increase pressure and counterclockwise to decrease pressure.

After adjusting to the working pressure, be sure to press down the pressure regulating nut to fix it.

When adjusting the pressure, there will be a small amount of leakage, which is a normal phenomenon.

Referring to the torque comparison table, adjust the power adjustment knob to the appropriate position, 1 is the minimum, 4 is the maximum.

This system allows the operator to reduce the maximum output power in the forward direction. But the power management system has a reverse

output power is not affected.

The power level indication is for reference only and does not indicate specific power. Using a variable stem, it is possible to

to further adjust the forward or reverse output power.

Read recommendations:

AK22-080 Pneumatic C-Hog Ring Plier (2.0 coil)

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

GP61-200 Emulsion Submersible Pump

2023-06-29RZ21-020 Pneumatic Rammer

2023-06-27LH12 Series Chain Hoist

2023-05-11AN22-8000 Pneumatic Torque Wrench (straight shaft)

2023-06-27CB21-200 Pneumatic Band Saw - Aluminum Alloy Series

2023-06-16CB21-065 Pneumatic Band Saw - Aluminum Alloy Series

2021-06-07DP21-060 Pneumatic Two Hand Operation Drill

2021-06-15CD31-380 Hydraulic Concrete Chainsaw

2023-06-16CS21-120丨Pneumatic Handheld Circular Saw

2023-06-17CS21-100丨Pneumatic Handheld Circular Saw

2021-06-08AN23-2500 Pneumatic Torque Wrench (Angle Shaft)

2024-03-12OW64-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10GA21-125 Pneumatic Wet Grinder

2023-06-28DM11-050 Electric Magnetic Drill

2022-12-30AN51-600 Charging CNC Torque Wrench

2022-12-27RH31-1550 Hydraulic Chipping Hammer

2023-06-27LH22-005 Pneumatic Hoist

2023-06-29RH21-1100 Pneumatic Chipping Hammer

2021-06-16DC21-400 Pneumatic Core Drill

2023-01-03GG21-100 Pneumatic Angle Grinder

2022-12-28CB61-310丨Emulsion Band Saw

2023-06-17CR21-005 Light Pneumatic Reciprocating Saw

2021-06-07DM31-013 Hydraulic Magnetic Drill

2023-06-19LH22-006 Pneumatic Hoist

2023-06-29AN51-8000 Electric servo CNC Torque Wrench

2023-06-27AW22-4000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15AN31-35000 Hydraulic Torque Wrench

2023-06-27AN71-20000 Torque Multiplier

2023-06-29AN22-1800 Pneumatic Torque Wrench (Straight Shaft)

2023-06-27AN31-7500 Hydraulic Torque Wrench

2023-06-27Accessories

Diamond Saw Blades

2023-06-06Pipe Fixed Clamps丨CB861-18

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Hydraulic Pump Station

2023-06-07Platform Clamps丨CB863-19

2023-06-06Integrated Hollow Drill Bits丨DC81

2023-06-07Optional Accessories

2023-06-07Abrasive Blades

2023-06-07Alloy Saw Blades丨CR811-150/152

2023-06-06Hydraulic Regulating Valve

2023-06-07Alloy Drill Bits丨813 Series

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Alloy Saw Chains丨CC812/CC816 Series

2023-06-06Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Drill Bit Extension Rods丨DC88 Series

2023-06-07Regular Saw Chains丨CC811 Series

2023-06-06Diamond Saw Chains

2020-06-13Diamond Saw Blades

2023-06-06Alloy Saw Blades丨CR812 Series

2023-06-06Alloy Saw Blades

2023-06-06Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Pin

2023-06-07Alloy Saw Blades

2023-06-06Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Alloy Twist Drill Bits丨DB81 Series

2023-06-06Tool Bits

2023-06-07Shovel Blades

2023-06-07Filter assy.

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07

You are here: >

You are here: >