- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Application scope and daily maintenance method of hydraulic bolt tensioner

source:Industry News release time:2022-09-20 Article author:yu Popular:Air band saw

The hydraulic bolt tensioner is referred to as the hydraulic tensioner. The function of its power element is to convert the mechanical energy of the prime mover into the pressure energy of the liquid. It refers to the oil pump in the hydraulic system, which provides power to the entire hydraulic system. So, what is the scope of application of hydraulic bolt tensioners? What are the advantages of hydraulic bolt tensioners? What are the daily maintenance methods for hydraulic bolt tensioners? These problems are of concern to many users, and Zhonghong Precision will analyze them with you below.

Scope of application of hydraulic bolt tensioner:

The hydraulic bolt tensioner has a wide range of applications, mainly in the fields of electric power, shipbuilding industry, metallurgical coal mine, petrochemical industry, heavy machinery and so on.

Advantages of hydraulic bolt tensioner:

1. Mineral oil is generally used as the working medium, the relative moving surface can be self-lubricated, and the service life is long.

2. Light weight, small size, small motion inertia and fast reaction speed.

3. Various components of hydraulic transmission can be arranged conveniently and flexibly according to needs.

4. Overload protection can be realized automatically.

5. The operation and control are convenient, and multiple bolts can be tightened at the same time. Save labor costs.

6. It is easy to realize linear motion.

7. It is easy to realize the automation of the machine. When the electro-hydraulic joint control is adopted, not only a higher degree of automatic control process can be realized, but also remote control can be realized.

8. It can be used as a device for applying axial force for hydraulic interference connection for top pressure installation.

Daily maintenance method of hydraulic bolt tensioner:

1. It must be operated in strict accordance with the method and program required by the manual, and the input working pressure and bolt stretching length of the hydraulic tensioner cannot be arbitrarily increased, so as to avoid damage to the sealing ring and related matching parts.

2. After finishing the work, it should be wiped clean and properly kept, especially the oil inlet interface should not seep into the dust (after the construction is completed, the quick joint part should be covered with a dust cap) to prevent damage to the oil cylinder and piston after entering the oil cylinder.

3. When replacing the O-ring and other accessories, pay attention to the fit to ensure the sealing effect.

4. The working fluid is L-HM32 or L-HM46 hydraulic oil. It is strictly forbidden to use alcohol, water, glycerin, brake oil, ordinary engine oil, etc. as working fluid.

5. All parts of the stretcher should always be kept clean, and there should be no dust or dirt around the oil pump, oil cylinder and rubber hose.

6. The working fluid should be replaced once a year, and it must be filtered and cleaned with a 120-200 mesh filter.

7. The high-pressure hose should be kept properly, and should not be corroded by corrosive gases and liquids. Due to long-term use and storage, the hose is easy to age, and should be checked regularly and replaced. The hose shall be pressure tested once a year.

8. When replacing the cylinder seal, the seal must be installed in the sealing groove, otherwise the pressure cannot be built up.

Read recommendations:

Alloy Twist Drill Bits丨DB81 Series

Alloy Saw Blades丨CR811-150/152

The key point of high quality of the most representative bolt tensioner!Air hacksaw company

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

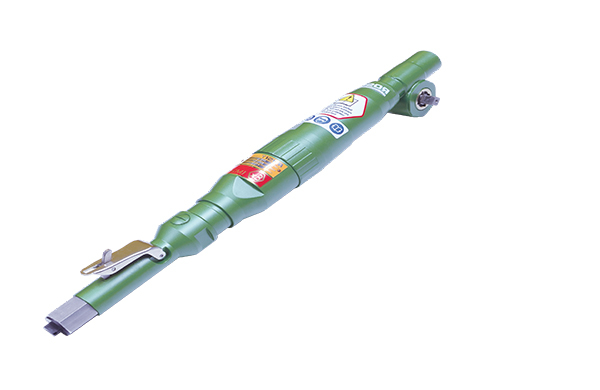

RC21-350 Pneumatic Long Reach Scalers

2021-06-15CB61-260丨Emulsion Band Saw

2023-06-17AW41-1500 Emulsion Impact Wrench

2020-06-13CC20-380 Pneumatic Chainsaw

2020-06-13AN23-8000 Pneumatic Torque Wrench (Angle Shaft)

2024-03-12CD31-630 Hydraulic Concrete Chainsaw

2023-06-16DB21-018 Pneumatic Rotary Drill Heavy Duty

2020-06-13AN21-100 Pneumatic Nut Runner

2021-06-15AW21-2700 Pneumatic Impact Wrench (Ex-proof Series)

2022-12-19AW21-6000 Pneumatic Impact Wrench (Ex-proof Series)

2022-12-19AK22-130 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29DH21-016 Pneumatic Hammer Drill

2020-06-13CC20-430 Pneumatic Chainsaw (3.0 kw Series)

2023-06-02OW63-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10CR21-015 Heavy Pneumatic Reciprocating Saw

2021-05-10AN22-1800 Pneumatic Torque Wrench (Straight Shaft)

2023-06-27OF23-520 Pneumatic Fan (light/medium)

2022-12-29LH22-005 Pneumatic Hoist

2023-06-29RH21-1100 Pneumatic Chipping Hammer

2021-06-16CC21-250 Pneumatic Chainsaw (1.0KW Series)

2020-06-13AK51-080 Pneumatic C-Hog Ring Plier (Charging/Manual 1.5 coil)

2023-06-29CN21-2432 Nut Cutter丨Manual Integrated Nut Cutter

2023-06-17AN32-5000 Hollow Hydraulic Wrench

2023-06-27DM21-016 Pneumatic Magnetic Drill

2022-12-15CB21-120 Pneumatic Band Saw - Aluminum Alloy Series

2023-01-06CB31-310 Hydraulic Band Saw

2023-06-16AN11-8000 Electric servo CNC Torque Wrench

2023-06-27CR21-002 Light Pneumatic Reciprocating Saw

2021-06-07RH31-1800 Hydraulic Chipping Hammer

2023-06-27AN32-40000 Hollow Hydraulic Wrench

2023-06-27Accessories

Alloy Drill Bits丨812 Series

2023-06-06Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Grinding Disc

2023-06-07Alloy Twist Drill Bits丨DB81 Series

2023-06-06Pin

2023-06-07Drill Bit Extension Rods丨DC88 Series

2023-06-07Alloy Saw Blades丨CR814 Series

2023-06-06Alloy Drill Bits丨811 Series

2023-06-06Filter assy.

2023-06-07Integrated Hollow Drill Bits丨DC81

2023-06-07Clamps

2023-06-06Alloy Drill Bits丨813 Series

2023-06-06Alloy Saw Blades

2023-06-06Abrasive Blades

2023-06-07Oiler

2020-06-13Non-metallic Alloy Saw Blades

2023-06-06Core Drill Morse Taper Sleeves

2023-06-07Chisels

2023-06-07Split Hollow Drill Bits丨DC82

2023-06-07Alloy Saw Blades丨CR811-150/152

2023-06-06Diamond Saw Blades

2023-06-06Shovel Blades

2023-06-07Guide Bars

2023-06-06Alloy Saw Blades丨CR812 Series

2023-06-06Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Tool Bits

2023-06-07Regular Saw Chains丨CC811 Series

2023-06-06Alloy Twist Drill Bits

2023-06-06Carborundum Saw Chains

2023-06-06

You are here: >

You are here: >