- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Analysis of the advantages and disadvantages of imported hydraulic wrenches and domestic hydraulic w

source:Industry News release time:2021-11-13 Article author:Rosit Popular:Air band saw

In the industry of hydraulic wrenches, the general customer will have the idea that imported hydraulic wrenches are better than domestic ones?

Why is this? Because many people think that although imported products are expensive, they have good quality and advanced technology, and the products produced can last a long time.

Although the price of domestic products is cheap, because the technology is relatively backward for imported ones, more and more people choose imported hydraulic wrenches. Next, let's take a look at the advantages and disadvantages of imported hydraulic wrenches and domestic hydraulic wrenches.

Imported hydraulic wrench

1. Most of the imported brands are relatively large, so the after-sales service part is relatively complete, but because the after-sales service is too strict, many customers' problems cannot be solved in time.

2. Imported hydraulic wrench sealing system adopts imported sealing ring, which can withstand long-term work under 70Mpa pressure, slow aging, and relatively long service life.

3. Imported hydraulic wrench has the characteristics of titanium alloy material, light weight, small size, large torque, etc. The unit weight can provide the maximum torque output, ensuring durability, reliability and safety.

4. The safety factor of imported high-pressure hose is 4 to 1, the working pressure is 70Mpa, the burst pressure is 280Mpa, the exterior is made of thermoplastic polyurethane material, and the interior is designed with 4 layers, of which 2 layers are high-strength steel wires.

Domestic hydraulic wrench

1. Domestic hydraulic wrenches are generally made of alloy steel and are heavy. The actual weight of a 36000Nm hydraulic wrench is about 50kg. Although the steel reaction arm has a certain strength, it is brittle and prone to breakage at the weaker link.

2. Domestically produced hydraulic wrenches are relatively mature in terms of sealing technology, but working at pressures above 60Mpa will cause unstable performance and other problems, which are very prone to damage, leading to oil leakage in the hydraulic wrench working head and short service life.

3. The outer layer of the high-pressure hose of the domestic hydraulic wrench is rubber wrapped, the safety factor is less than 2, and the internal two-layer design. The easy aging of the rubber leads to the extremely short service life of the tubing. If it cannot be replaced in time, it is very easy to cause safety hazards.

Read recommendations:

AN31-70000 Hydraulic Torque Wrench

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

RZ21-016 Pneumatic Rammer

2023-06-27DP22-220 Pneumatic Column Drill

2023-06-19LH22-003 Pneumatic Hoist

2023-05-11GP61-050 Emulsion Submersible Pump

2022-12-29CC20-380 Pneumatic Chainsaw

2020-06-13DH21-050 Pneumatic Hammer Drill

2021-06-10RH31-2100 Hydraulic Chipping Hammer

2022-12-27DP61-060 Emulsion Two Hand Operation Drill

2020-11-24RH21-230 Pneumatic Chipping Hammer

2021-06-16LH61-050 Emulsion Hoist

2023-06-29CS21-180 Pneumatic Handheld Circular Saw

2020-06-13AW41-1500 Emulsion Impact Wrench

2020-06-13LW21-010 Pneumatic Winch

2023-01-06AN71-7500 Torque Multiplier

2023-06-29AK22-065 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29DL21-016 Pneumatic Pistol Hammer Drill

2021-06-10CB22-260 Pneumatic Band Saw - Stainless Steel Series

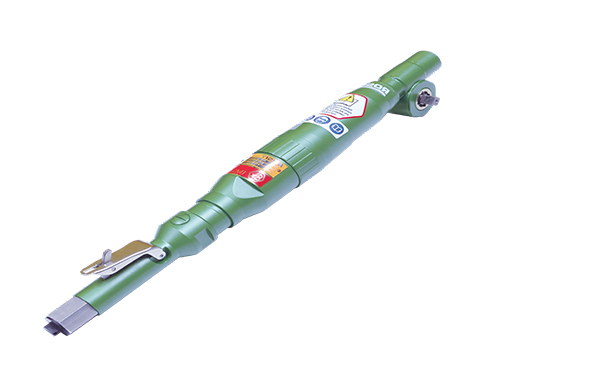

2023-06-16AN22-1800 Pneumatic Torque Wrench (Straight Shaft)

2023-06-27DP22-150 Pneumatic Column Drill

2020-06-13AW22-6000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15AN11-4500 Electric servo CNC Torque Wrench

2023-06-27AK71-130 Manual C-Hog Ring Plier (1.5 coil)

2022-12-12CC22-630 Pneumatic Chain Saw (5.0KW Series)

2023-06-14CD31-250 Hydraulic Concrete Chainsaw

2020-06-13LH31 Series Hydraulic Hoist

2023-05-11LW21-005 Pneumatic Winch

2023-01-06LH61-005 Emulsion Hoist

2023-06-29CB11-310 Electric Band Saw

2023-06-16DA21-100 Pneumatic Angle Drill

2023-06-19AN31-100000 Hydraulic Torque Wrench

2023-06-27Accessories

Core Drill Morse Taper Sleeves

2023-06-07Pipe Fixed Clamps丨CB861-18

2023-06-06Alloy Twist Drill Bits

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06Diamond Saw Blades

2023-06-06Alloy Saw Blades丨CR812 Series

2023-06-06Alloy Saw Blades

2023-06-06Cross Clamps丨CB862-22

2023-06-06Hydraulic Pump Station

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Rail Clamps丨CB864-12

2023-06-06Tool Bits

2023-06-07Tool Bits

2023-06-07Alloy Drill Bits丨812 Series

2023-06-06Diamond Saw Blades

2023-06-06Pin

2023-06-07Alloy Sleeves

2023-06-07Oiler

2020-06-13Alloy Drill Bits丨811 Series

2023-06-06Cutting Blades

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Alloy Drill Bits丨813 Series

2023-06-06Alloy Saw Blades丨CR815 Series

2023-06-06Water Pump

2020-06-13Carborundum Saw Chains

2023-06-06Filter assy.

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Carbide Inserts Twist Bits丨DB82 Series

2023-06-06

You are here: >

You are here: >