- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

What are the advantages of vortex air pump air knife drying and traditional drying

source:Industry News release time:2021-07-26 Article author:Rosit Popular:Air band saw

Let us outline the domestic stainless steel air knife drying program. The air knife drying is mainly dried by hot air with compressed air and by hot air with a high-pressure vortex fan. The installation is convenient and the use is more convenient. On the production line of filling products, the outer surface of the bottles of already filled products, such as wine, soda, pure water, etc., should be affixed with outer bottle labels, printed text or boxed. In order to achieve a better paste effect, it is required to dry the surface of the packaging bottle. In the actual production process, the packaging bottle is generally dried or blow-dried.

In production, the drying generally adopts a combined brush-drying type or a hot oven drying type, and the bottle brushing device mainly uses a brush to rotate to remove water droplets on the bottle wall. Due to the contact treatment method, the effect of brushing the bottle is closely related to the appearance of the bottle. The printing effect of cylindrical bottles is good, and some parts of the surface of special-shaped bottles such as non-rotating bodies cannot touch the brush, and there is still water film on the outer wall of this part after the bottle is brushed. In addition, in the process of use, the brush is easy to accumulate dirt, which may be transferred to the outer wall of the bottle and affect the quality of the packaging.

The drying oven has a simple structure and complete drying, but its thermal power is high, and the working temperature is high. When the automatic production line is arranged, the area isolation treatment is required. When drying, the water takes a long time to completely evaporate, which is not suitable for high output. When the transfer system is blocked during the work, such as bottle jam, bottle pouring, etc., the packaging bottle stays in the oven for too long, which may cause the bottle to burst.

In addition, for product surfaces that require high cleanliness, after cleaning and rinsing procedures, drying methods are generally not used. This is because not only must the surface of the packaging bottle be guaranteed to be dry, but also the product surface and rinsing water must be resolved. Contains impurities and causes water spots after drying. The use of vortex air pump air knife drying method, that is, the advantage of pneumatic wind speed is used in the packaging process of filling products. The high-pressure airflow is used to complete the accumulation and acceleration of the airflow through the air knife to blow the residual water droplets. The airflow can be used to remove the residual water droplets on the surface of the product. Moisture is easily blown off.

In actual operation, the smaller the height of the air knife nozzle gap, the greater the resistance of the jet airflow, and the higher the heat converted by the entire system. According to the operating characteristic curve of the fan, its life will be shorter. . Therefore, when setting the gap height, it is necessary to weigh the jet speed of the air knife and the operating life of the high-pressure fan to determine it. The shorter the guide section of the injection port, the better, in order to reduce unnecessary friction loss, but it should not be too short. It is best to use 3 times the height of the gap design, otherwise it will not have a good guiding air jet effect, which will cause the jet The airflow cannot be concentrated on the surface of the packaging bottle, resulting in the remaining water droplets can not be effectively blown off. During the operation of the drying and dewatering equipment, the pressure and air volume characteristics of the fan are a curve. In the non-rated state, the air flow rate of the nozzle can be dynamically obtained by the method of experimental measurement, so as to adjust the operating state of the fan in time.

Read recommendations:

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

RH31-2100 Hydraulic Chipping Hammer

2022-12-27CB21-065 Pneumatic Band Saw - Aluminum Alloy Series

2021-06-07DC11-300 Electric Core Drill

2023-06-20RH31-1550 Hydraulic Chipping Hammer

2023-06-27RH31-1000 Hydraulic Chipping Hammer

2023-06-27CS21-100丨Pneumatic Handheld Circular Saw

2021-06-08DM31-030 Hydraulic Magnetic Drill

2020-06-13AN71-1500 Torque Multiplier

2022-12-27LW21-025 Pneumatic Winch

2023-06-29AN71-15000 Torque Multiplier

2023-06-29DM21-045 Pneumatic Magnetic Drill

2022-12-15CB22-200 Pneumatic Band Saw - Stainless Steel Series

2023-06-16CN22-110130 Nut Cutter丨Split-type Nut Cutter

2023-06-17CC22-630 Pneumatic Chain Saw (5.0KW Series)

2023-06-14AN51-3000 Electric servo CNC Torque Wrench

2023-06-27AK22-065 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29CS21-180 Pneumatic Handheld Circular Saw

2020-06-13CB11-260 Electric Band Saw

2023-06-16CS22-180 Pneumatic Trolley Circular Saw

2021-06-08DM22-030 Pneumatic Rail Drill

2023-06-19DP61-110 Emulsion Two Hand Operation Drill

2022-12-14AW41-3500 Emulsion Impact Wrench

2023-06-21GA21-178 Pneumatic Wet Grinder

2023-06-28RH31-1350 Hydraulic Chipping Hammer

2023-06-27DH21-026 Pneumatic Hammer Drill

2021-06-10AN11-3000 Electric servo CNC Torque Wrench

2023-06-27RC21-850 Pneumatic Long Reach Scalers

2023-06-27CN22-2434 Nut Cutter丨Split-type Nut Cutter

2023-06-17RH31-1800 Hydraulic Chipping Hammer

2023-06-27DL21-016 Pneumatic Pistol Hammer Drill

2021-06-10Accessories

Platform Clamps丨CB863-19

2023-06-06Alloy Twist Drill Bits

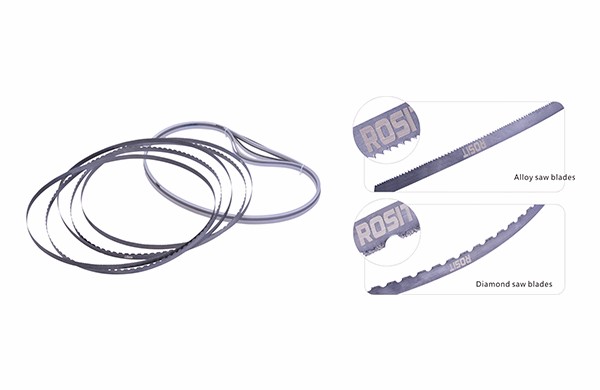

2023-06-06Alloy Saw Blades丨CR811-150/152

2023-06-06Tool Bits

2023-06-07Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Tool Bits

2023-06-07Diamond Saw Blades

2023-06-06Hydraulic Pump Station

2023-06-07Alloy Saw Blades丨CR816 Series

2023-06-06Filter assy.

2023-06-07Alloy Saw Blades丨CR814 Series

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Alloy Drill Bits丨811 Series

2023-06-06Alloy Saw Blades

2023-06-06Diamond Saw Blades

2023-06-06Carbide Hollow Bits丨DM816 Series

2023-06-06Ex-proof Sleeves KIT

2023-06-07Alloy Guide Bars丨CC814 Series

2023-06-06Pipe Fixed Clamps丨CB861-18

2023-06-06Filter assy.

2023-06-07Alloy Twist Drill Bits丨DB81 Series

2023-06-06Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Pipe Fixed Clamps丨CB861-12

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Cutting Blades

2023-06-07Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Alloy Drill Bits丨812 Series

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06

You are here: >

You are here: >