- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

How to maintain the electric drill?

source:Industry News release time:2021-05-06 Article author:Rosit Popular:Air band saw

Due to the need for ventilation and heat dissipation of electric drills, there is a lot of internal dust in long-term use. The dust will mix and deteriorate the lubricating oil on the gears and bearings (sliding sleeves) and dry up and increase wear, especially when used in alternative types. In order to ensure the rotation accuracy of the electric drill and reduce the excessive clearance caused by the wear of the bearing (slide sleeve), it is extremely necessary to keep the interior clean and add grease to lubricate.

Method:

Loosen a few self-tapping screws or screws outside the electric drill; lay it flat and open half of the shell; generally the structure of the new-style electric hand drill is semi-embedded, that is, all the machines and electrical components are installed in the other half of the shell;

Carefully remove the carbon brush first, then the drill chuck end, then gently lift the motor to take out the rotor (don't scratch the enameled wire), wipe the commutator on the rotor (the one in contact with the carbon brush), if it is too dirty Or if the abrasion is severe, it can be polished with emery cloth and then polished with water or metallographic sandpaper until it is bright.

If the front and rear bearings of the rotor are sealed, they can be wiped clean. If the seal is broken, they should be replaced in time. Wipe the helical gear shaft in front of the rotor clean.

Wipe clean the oil inside the shell. Clean the helical gear and the bearings (or bushings) on both ends of the drill chuck rod.

Reinstall the unloaded stuff, first install the rotor; then install the drill chuck rod helical gear; install the carbon brush, if the carbon brush is shorter than 7-8 mm, replace it in time. The carbon brush should be installed and flattened. Finally, find a little "Mobil" or "Shell" grease and add it between the gear pair and the bearing (or sleeve). All parts should be installed and flattened and checked for correctness. The other half can be covered. Tighten the screw, turn it by hand and feel no stuck, then power on and try it.

What should be paid attention to when using electric drill

1. The diameter of the drill used cannot exceed the allowable value of the electric drill.

2. The drill bit must be clamped with a key, and other tools cannot be used to strike the drill chuck.

3. Do not use too much force when drilling to prevent the motor from overloading. If the rotation speed is found to be reduced, the power supply should be cut off immediately for inspection.

4. The sporadic machining parts must be firmly on the fixture.

5. Cannot wear gloves.

Read recommendations:

AW22-8000 Pneumatic Impact Wrench (Ultra-Light Series)

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

RH21-4500 Pneumatic Chipping Hammer

2021-06-15AN71-3500 Torque Multiplier

2023-06-29AN21-550 Pneumatic Nut Runner

2020-06-13AK21-080 Pneumatic C-Hog Ring Plier (1.5 coil)

2023-06-29CS21-065 Pneumatic Handheld Circular Saw

2021-06-08LH12 Series Chain Hoist

2023-05-11LW21-002 Pneumatic Winch

2023-06-29CB22-310 Pneumatic Band Saw - Stainless Steel Series

2023-06-16AN21-400 Pneumatic Nut Runner

2022-12-20DA21-032 Pneumatic Angle Drill

2023-06-19GG21-230 Pneumatic Angel Grinder

2021-06-15OF27-360 Heavy Fixed Fan

2023-06-28DC11-400 Electric Core Drill

2023-06-20DL21-016 Pneumatic Pistol Hammer Drill

2021-06-10DM31-035 Hydraulic Magnetic Drill

2022-12-30AW22-6000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15DM22-023 Pneumatic Rail Drill

2023-06-19DP22-220 Pneumatic Column Drill

2023-06-19CB31-260 Hydraulic Band Saw

2023-06-16GG11-230 Electric Angle Grinder

2023-06-28AW41-2500 Emulsion Impact Wrench

2021-06-15RC21-1200 Pneumatic Long Reach Scalers

2023-06-27DM31-013 Hydraulic Magnetic Drill

2023-06-19DP21-060 Pneumatic Two Hand Operation Drill

2021-06-15CD31-380 Hydraulic Concrete Chainsaw

2023-06-16RC21-850 Pneumatic Long Reach Scalers

2023-06-27AN71-1500 Torque Multiplier

2022-12-27LH61-032 Emulsion Hoist

2023-06-29DM11-080 Electric Magnetic Drill

2023-06-19CC21-250 Pneumatic Chainsaw (1.0KW Series)

2020-06-13Accessories

Hydraulic Regulating Valve

2023-06-07Abrasive Blades

2023-06-07Water Pump

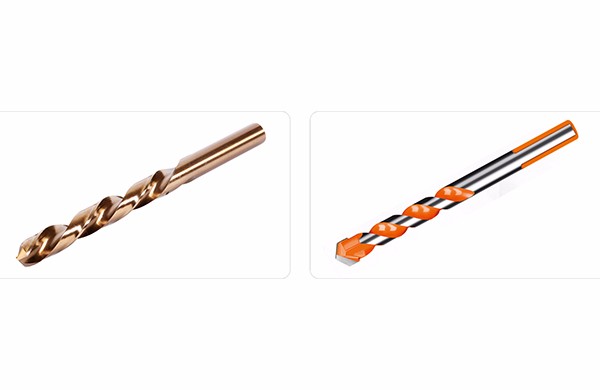

2020-06-13Alloy Twist Drill Bits

2023-06-06Filter assy.

2023-06-07Guide Bars

2023-06-06Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Diamond Saw Blades

2023-06-06Filter assy.

2023-06-07Rail Clamps丨CB864-12

2023-06-06Alloy Saw Blades

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Tool Bits

2023-06-07Carborundum Saw Chains

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Alloy Saw Blades丨CR816 Series

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Optional Accessories

2023-06-07Chisels

2023-06-07Integrated Hollow Drill Bits丨DC81

2023-06-07Oiler

2020-06-13Platform Clamps丨CB863-19

2023-06-06Hydraulic Pump Station

2023-06-07Alloy Saw Blades

2023-06-06Alloy Sleeves

2023-06-07Shovel Blades

2023-06-07Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06Alloy Drill Bits丨811 Series

2023-06-06Clamps

2023-06-06

You are here: >

You are here: >