- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Regular maintenance of hydraulic wrenches is very necessary

source:Industry News release time:2021-09-07 Article author:Rosit Popular:Air band saw

When dealing with (chǔ lǐ) machine faults, many auto mechanics use a very powerful auxiliary work, which is a hydraulic wrench. The hydraulic wrench can provide powerful hydraulic power to drive the machine to operate according to requirements, and at the same time, the effect is more obvious in the tightening process, which greatly reduces the difficulty of manpower operation and control. In fact, the maintenance engineer has a certain understanding of the related information of hydraulic wrenches (Find out), but while mastering the principle of operation and the nature of the work, people should also be reminded to pay attention to the maintenance of the machine. This is to extend the life of the machine. The key (explanation: an important part of a metaphor).

The lifetime of the hydraulic wrench, in addition to the correct operation and control as required during operation, must also be maintained and repaired consistently. Many people think that the newly-purchased hydraulic wrench has a good performance advantage (explanation: it can overwhelm the other party’s favorable situation), so there is no need for lubrication and maintenance, and the maintenance only shows that the machine is not running flexibly or cannot work normally. In fact, it is already very at this time. It's too late. The hydraulic wrench is no longer facing a minor problem (Emerson), and the overall replacement problem is no longer a problem. The current situation described indicates that the machine has suffered a serious failure. So what issues should be paid attention to in the regular maintenance of hydraulic wrenches?

Regular maintenance should first pay attention to the time issue, which is generally divided into daily maintenance and monthly maintenance. The former is best to be simply wiped or tightened after the machine is used (chǔ lǐ), and lubricating oil can also be applied as needed; the latter Maintenance requires polishing or renewal of damaged parts.

In addition, when maintaining hydraulic wrenches, attention should also be paid to the selection of storage environment to ensure that the warehouse is ventilated and dry. Hydraulic wrenches cannot be placed together with acid and alkali liquids. It should not be placed in a damp and dark corner, as this will aggravate the corrosion of the machine, thereby affecting the performance (showing inherent ability). The hydraulic wrench transmits power to the working head through the high-pressure oil pipe and the hydraulic pump, which drives the working head to tighten or loosen the nut. The hydraulic pump can be driven by electricity or compressed air. The working head of the hydraulic wrench is mainly composed of three parts, the frame (also called the shell), the oil cylinder and the transmission parts. The output force of the oil cylinder, the piston rod of the oil cylinder and the transmission part form a motion pair. The distance from the center of the oil cylinder to the center of the transmission component is the hydraulic wrench amplification arm. The oil cylinder output multiplied by the arm is the theoretical output torque of the hydraulic wrench. The actual output torque is smaller than the theoretical output torque.

Read recommendations:

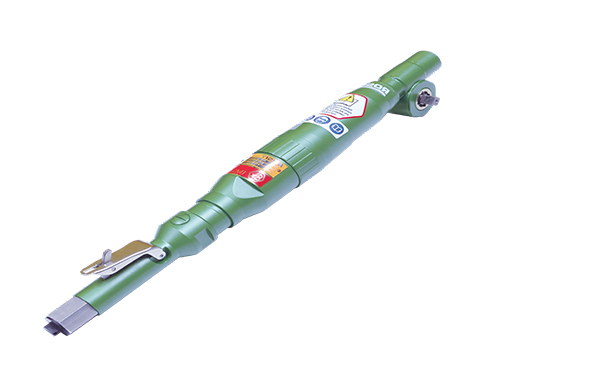

AW22-750 Pneumatic Impact Wrench (Ultra-Light Series)

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

RH31-1400 Hydraulic Chipping Hammer

2023-06-27AW21-2700 Pneumatic Impact Wrench (Ex-proof Series)

2022-12-19DL21-008 Pneumatic Pistol Hammer Drill

2023-06-19CB61-310丨Emulsion Band Saw

2023-06-17DM11-023 Electric Magnetic Drill

2023-06-19CB21-160 Pneumatic Band Saw - Aluminum Alloy Series

2023-06-16AK51-110 Pneumatic C-Hog Ring Plier (Charging/Manual 1.5 coil)

2023-06-29DC11-100 Electric Core Drill

2023-01-03LH61-050 Emulsion Hoist

2023-06-29AW41-2500 Emulsion Impact Wrench

2021-06-15LH11 Series Manual Chain Hoist

2023-05-11AN31-100000 Hydraulic Torque Wrench

2023-06-27GA21-100 Pneumatic Wet Grinder

2022-12-28CC23-530 Pneumatic Chainsaw Heavy-Duty (3.5KW Series)

2023-06-14CC21-380 Pneumatic Chainsaw (3.0 kw Series)

2022-12-08OF27-100 Heavy Fixed Fan

2022-12-29DP22-260 Pneumatic Column Drill

2023-06-19CN21-2432 Nut Cutter丨Manual Integrated Nut Cutter

2023-06-17CD31-500 Hydraulic Concrete Chainsaw

2023-06-16CD22-500 Pneumatic Concrete Chainsaw (5.0KW)

2023-06-16DM11-080 Electric Magnetic Drill

2023-06-19AW41-1500 Emulsion Impact Wrench

2020-06-13LH31 Series Hydraulic Hoist

2023-05-11LH61-005 Emulsion Hoist

2023-06-29AN31-4500 Hydraulic Torque Wrench

2023-06-27CN22-70115 Nut Cutter丨Split-type Nut Cutter

2022-12-12CC21-250 Pneumatic Chainsaw (1.0KW Series)

2020-06-13OF22-500 Pneumatic Fan (light/medium)

2022-12-29DB21-022 Pneumatic Rotary Drill Heavy Duty

2023-06-19AN32-23000 Hollow Hydraulic Wrench

2023-06-27Accessories

Alloy Saw Blades

2023-06-06Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Abrasive Blades

2023-06-07Alloy Saw Blades

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Hydraulic Regulating Valve

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Tool Bits

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Alloy Saw Blades丨CR811-150/152

2023-06-06Tool Bits

2023-06-07Clamps

2023-06-06Diamond Saw Chains

2020-06-13Alloy Saw Blades丨CR811 Series

2023-06-06Alloy Guide Bars丨CC814 Series

2023-06-06Alloy Drill Bits丨813 Series

2023-06-06Ex-proof Sleeves KIT

2023-06-07Alloy Drill Bits丨811 Series

2023-06-06Cross Clamps丨CB862-22

2023-06-06Platform Clamps丨CB863-19

2023-06-06Diamond Saw Blades

2023-06-06Rail Clamps丨CB864-12

2023-06-06Carborundum Saw Chains

2023-06-06Filter assy.

2023-06-07Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Alloy Twist Drill Bits

2023-06-06Alloy Saw Chains丨CC812/CC816 Series

2023-06-06Pin

2023-06-07Carbide Inserts Twist Bits丨DB82 Series

2023-06-06

You are here: >

You are here: >