- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

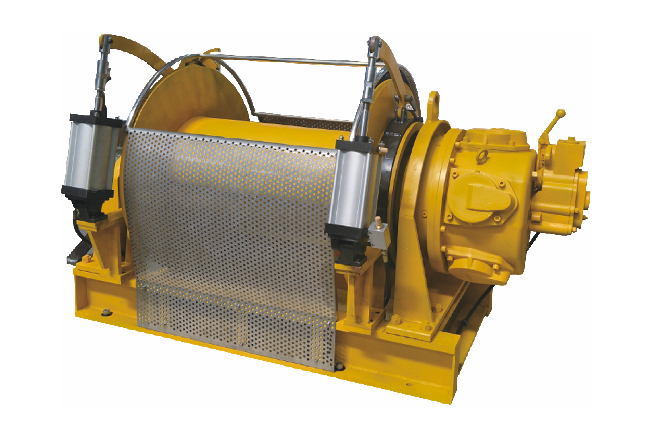

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

2.5m frequency conversion winch configuration scheme

source:Industry News release time:2021-05-10 Article author:Rosit Popular:Air band saw

Mine hoists rely on friction to lift heavy objects. They are generally used in large deep wells and mines with heavier lifting tonnages. According to the layout, they can be divided into: pit tower multi-rope friction hoist and floor-standing multi-rope friction hoist. Their structure is composed of a lifting container, a lifting wire rope, a friction wheel, a guide wheel (or sky wheel), and a tail rope.

During the operation of large construction machinery, corresponding supporting systems such as electrical control systems and signal control systems are needed. As the hoist electric control system for safe operation of mine hoists in mine production, master its correct operation method It is of great significance to the entire project production. Mine hoist is a kind of equipment mainly used in mines to achieve its working purpose by means of wire rope traction. The hoist manufacturer believes that it is mainly suitable for inclined roadways and small shafts on the ground or underground of coal mines, metal mines and non-metal mines. For such an important mining hoist in the heavy industry industry, we must do a good job in daily maintenance and maintenance.

1. Regular inspections. Regularly check the safety protection settings of the mine hoist;

2, the lifting container needs to be empty. During the rope adjustment operation of the double drum hoisting winch, the hoisting container must be empty. After the rope adjustment is completed, check the correctness of the interlock valve position, and the shut-off valve must be closed;

3, lower heavy objects, electric brake;

4. Keep the surface of the brake disc and brake shoe clean;

5. When replacing the brake shoes, the brake shoes must be replaced in groups, and the newly replaced brake shoes should be the same as the original brake shoes.

Maintenance work of mine hoist:

1. The operating environment should always be kept dry. Sichuan explosion-proof winches are sold. The surface of the motor should be kept clean, and the air inlet should not be obstructed by dust, fibers, etc.;

2. When the thermal protection of the motor continues to operate, it should be ascertained whether the fault comes from the motor or overload or the setting value of the protection device is too low. After the fault is eliminated, it can be put into operation.

Mine hoists are widely used in mines. Because of their nature, they also play a more important role. However, in the process of use, mining hoists will inevitably not have some problems, except for problems. If the solution is resolved, the progress of the project will be delayed. A good way is to prevent these accidents in time. Let's take a look at how to do the maintenance of the mine hoist today!

1. The use environment should always be kept dry. Sichuan explosion-proof winches are sold. The surface of the motor should be kept clean, and the air inlet should not be obstructed by dust, fibers, etc.

2. When the thermal protection of the motor continues to operate, it should be ascertained whether the fault comes from the motor or overload or the setting value of the protection device is too low. After the fault is eliminated, it can be put into operation.

Mining hoist installation steps:

1. The mine hoist must be firmly installed on a solid concrete foundation. The surface of the foundation should be flat and horizontal to ensure that the mine hoist meets the vertical requirements after installation. A bucket elevator with a higher height should be connected to the adjacent buildings at the appropriate positions of the middle and upper casings to increase its stability. The hoist manufacturer prompts to install the lower parts first, fix the anchor bolts, and then install the middle casing, and then install the upper casing. The cabinet is installed successfully and the verticality is corrected. Measure with a straight line up and down the full height, the error should be less than 10. The upper and lower shafts should be parallel, and their axis should be in the same plane. When installing a bucket elevator with a lower height, the upper, middle and lower casings can be connected and aligned on the ground plane, and then the whole can be hoisted and fixed on the concrete foundation;

2. After the cabinet is installed, install the chain and hopper. The U-shaped screw used to connect the hopper is not only a chain joint, but also a fixing part of the hopper. The nut of the U-shaped screw must be tightened and reliably prevented from loosening;

3. After the chain and hopper are installed, they should be properly tensioned;

4. Add appropriate amount of oil and grease to the reducer and bearing seat respectively. The reducer is lubricated with industrial gear oil. Calcium-based or sodium-based butter can be used in the bearing seat;

5. Trial run. After the installation is completed, an empty test run should be carried out. Attention should be paid to dry running: no reverse rotation and no bumps. The idling operation is not less than 2 hours, there should be no overheating, the temperature rise of the bearing does not exceed 250C, and the temperature rise of the reducer does not exceed 300C. After 2 hours of idling, everything is normal and the load test can be carried out. Feeding should be even during the test run with load to prevent too much feed and block the lower part and cause "stuffy car".

Read recommendations:

AW22-750 Pneumatic Impact Wrench (Ultra-Light Series)

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

GG11-125 Electric Angle Grinder

2023-06-28OF22-880 Pneumatic Fan (light/medium)

2023-06-28LH22-003 Pneumatic Hoist

2023-05-11RH21-1450 Pneumatic Chipping Hammer

2021-06-16CR21-001 Light Pneumatic Reciprocating Saw

2021-06-07DA21-100 Pneumatic Angle Drill

2023-06-19LW21-025 Pneumatic Winch

2023-06-29AN32-5000 Hollow Hydraulic Wrench

2023-06-27OF23-880 Pneumatic Fan/ (light/medium)

2023-06-28DA21-015 Pneumatic Angle Drill

2022-12-15DP61-140 Emulsion Two Hand Operation Drill

2023-06-19RZ21-016 Pneumatic Rammer

2023-06-27LH22-002 Pneumatic Hoist

2023-06-29DP61-090 Emulsion Two Hand Operation Drill

2021-06-15RH21-1100 Pneumatic Chipping Hammer

2021-06-16AK51-080 Pneumatic C-Hog Ring Plier (Charging/Manual 1.5 coil)

2023-06-29AW21-600 Pneumatic Impact Wrench (Ex-proof Series)

2021-06-02DA21-022 Pneumatic Angle Drill

2023-06-19LH61-032 Emulsion Hoist

2023-06-29LH31 Series Hydraulic Hoist

2023-05-11AK22-130 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29AN23-750 Pneumatic Torque Wrench (Angle Shank)

2024-03-12AN31-15000 Hydraulic Torque Wrench

2023-06-27LW21-003 Pneumatic Winch

2023-06-29RH21-2500 Pneumatic Chipping Hammer

2021-06-15AN22-8000 Pneumatic Torque Wrench (Straight Shank)

2024-06-14OW61-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10OW62-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10CH31 series Hydraulic Pipe Cutter

2022-12-12DA21-075 Pneumatic Angle Drill

2023-06-19Accessories

Alloy Twist Drill Bits

2023-06-06Regular Saw Chains丨CC811 Series

2023-06-06Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Optional Accessories

2023-06-07Diamond Saw Chains

2020-06-13Pin

2023-06-07Water Pump

2020-06-13Carborundum saw Blades

2023-06-06Platform Clamps丨CB863-19

2023-06-06Drill Bit Extension Rods丨DC88 Series

2023-06-07Filter assy.

2023-06-07Oiler

2020-06-13Diamond Saw Blades

2023-06-06Tool Bits

2023-06-07Sleeve KIT

2023-06-07Alloy Drill Bits丨811 Series

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Diamond Saw Chains丨CC813 Series

2023-06-06Alloy Twist Drill Bits丨DB81 Series

2023-06-06Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Ex-proof Sleeves

2023-06-07Alloy Saw Blades丨CR811-150/152

2023-06-06Cross Clamps丨CB862-22

2023-06-06Abrasive Blades

2023-06-07Non-metallic Alloy Saw Blades

2023-06-06Carbide Hollow Bits丨DM818 Series

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07

You are here: >

You are here: >