- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Introduction of heavy-duty allen wrench

source:Industry News release time:2021-04-12 Article author:Rosit Popular:Air band saw

The heavy-duty hex wrench is a special tool with an L-shaped shape and used for a hexagon socket head screw. The hex rod is shaped. The heavy hex wrench is specially used to turn the hex screw. The model of this special tool is based on the size of the opposite side of the hexagon, and the size of the bolt has a standard.

The heavy-duty allen wrench is an industrial-grade special wrench. The specifications are generally S17~S120mm, which belong to the heavy-duty wrench series. The material is 45# steel or 40Cr. The explosion-proof hexagonal wrench used in the flammable and explosive industries is made of beryllium bronze or aluminum bronze, and the specifications are S6~S55mm.

The main scope of application is: petroleum refining and petrochemical industry, coal mines, oil fields, natural gas chemical industry, gunpowder industry, chemical fiber industry, paint industry, fertilizer industry, various pharmaceutical industries. Petroleum tankers and LPG vehicles, airplanes, warehouses dealing in flammable and explosive products, electrolysis workshops, communication machine assembly workshops, flammable and explosive industries that require tools to be rust-proof, wear-resistant and explosion-proof, etc.

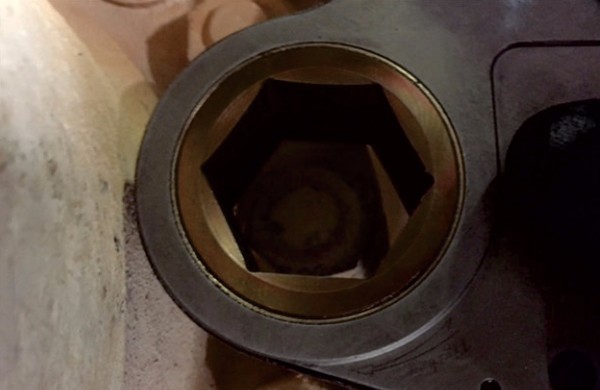

According to the torque requirements of the working space and the size of the bolt or nut, select the appropriate socket head. The sleeve has a short tubular shape, one end of which is hexagonal or dodecagonal, used to cover the bolt head; the other end has a square head hole, which is used to match the square tenon of the matching handle.

Types of hex socket wrenches

In addition to the common standard sleeves, there are many special sleeves, such as hexagonal long sleeves, hexagonal or dodecagonal flower-shaped sleeves, pneumatic sleeves, screwdriver sleeves and barrels. If the head is made of special-shaped bolts and nuts, special sleeves must be used for disassembly.

1. Hexagon socket

The depth of the hexagonal long sleeve is 3 times deeper than that of the standard sleeve. It is one of the commonly used modified sleeves in automobile maintenance work.

2Pneumatic sleeve

Allen socket wrench

Pneumatic sockets are specially matched with pneumatic impact wrenches. If ordinary sockets are used, pneumatic impact wrenches will produce instantaneous strong impacts during work, which may damage the sockets. The pneumatic sleeve is made of special chrome steel alloy, and the wall thickness is increased in the production process, the strength is reduced, and the toughness is enhanced, so that it can adapt to the harsh working environment.

3. Hexagonal pan-shaped sleeve

The flower-shaped sleeve is specially used to remove flower-shaped bolt head bolts. When disassembling, the flower-shaped sleeve can achieve surface contact with the bolt head, and adopts a curved structure, which can increase the disassembly torque while reducing the volume. In modern vehicles, the use of flower-shaped head bolts has gradually increased, and they are often used for door mounting bolts or stud bolts for intake manifolds.

Specification of hex socket wrench

According to the torque of the disassembled bolt and the working environment, the sleeve can be divided into three series: large, medium and small, and distinguished by the width of the square tenon of the matching handle

Read recommendations:

AN22-8000 Pneumatic Torque Wrench (Straight Shank)

AN22-6000 Pneumatic Torque Wrench (straight shaft)

Drill Bit Extension Rods丨DC88 Series

Is it necessary to install a vacuum filter on the vortex air pump?

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

CD22-630 Pneumatic Concrete Chainsaw (5.0KW)

2023-06-16GG21-178 Pneumatic Angel Grinder

2020-06-13OW11-020 Electric Mining Waterjet Cutting Machine

2023-05-10AN23-1800 Pneumatic Torque Wrench (Angle Shaft)

2024-03-12CB31-120 Hydraulic Band Saw

2020-06-13AN71-5500 Torque Multiplier

2023-06-29DA21-032 Pneumatic Angle Drill

2023-06-19RC21-350 Pneumatic Long Reach Scalers

2021-06-15AN11-2000 Electric servo CNC Torque Wrench

2023-06-27AN51-1600 Electric servo CNC Torque Wrench

2023-06-27DP61-110 Emulsion Two Hand Operation Drill

2022-12-14CB61-200丨Emulsion Band Saw

2023-06-17DL21-010 Pneumatic Pistol Hammer Drill

2021-06-10AW22-3500 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15DC11-150 Electric Core Drill

2023-06-20RH21-3500 Pneumatic Chipping Hammer

2021-06-15AN31-26000 Hydraulic Torque Wrench

2023-06-27AN21-550 Pneumatic Nut Runner

2020-06-13AN31-7500 Hydraulic Torque Wrench

2023-06-27DH21-030 Pneumatic Hammer Drill

2021-06-10CB21-200 Pneumatic Band Saw - Aluminum Alloy Series

2023-06-16CN21-2432 Nut Cutter丨Manual Integrated Nut Cutter

2023-06-17DC11-300 Electric Core Drill

2023-06-20CC20-530 Pneumatic Chainsaw (3.0 kw Series)

2023-06-14CB11-310 Electric Band Saw

2023-06-16OW62-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10AK22-080 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29DB21-050 Pneumatic Rotary Drill Heavy Duty

2023-06-19AN22-4500 Pneumatic Torque Wrench (Straight Shank)

2021-06-03LH22-010 Pneumatic Hoist

2023-06-29Accessories

Diamond Saw Chains

2020-06-13Pipe Fixed Clamps丨CB861-12

2023-06-06Shovel Blades

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Cross Clamps丨CB862-22

2023-06-06Alloy Saw Blades丨CR812 Series

2023-06-06Diamond Saw Blades

2023-06-06Alloy Guide Bars丨CC814 Series

2023-06-06Carborundum saw Blades

2023-06-06Platform Clamps丨CB863-19

2023-06-06Chisels

2023-06-07Optional Accessories

2023-06-07Rail Clamps丨CB864-12

2023-06-06Hydraulic Pump Station

2023-06-07Split Hollow Drill Bits丨DC82

2023-06-07Sleeve KIT

2023-06-07Alloy Drill Bits丨812 Series

2023-06-06Water Pump

2020-06-13Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Grinding Disc

2023-06-07Hydraulic Regulating Valve

2023-06-07Diamond Saw Chains丨CC813 Series

2023-06-06Filter assy.

2023-06-07Diamond Saw Blades

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Alloy Saw Blades丨CR811-150/152

2023-06-06Tool Bits

2023-06-07Alloy Saw Blades

2023-06-06Core Drill Morse Taper Sleeves

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06

You are here: >

You are here: >