- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

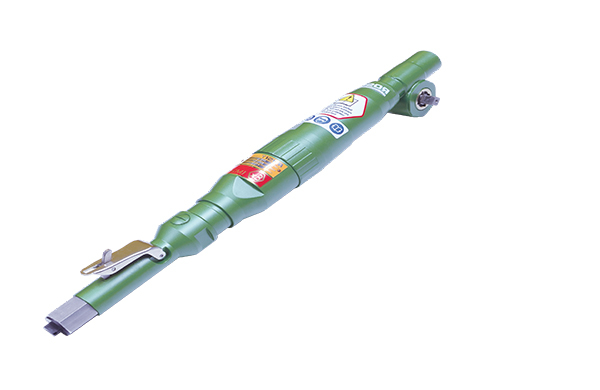

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Precautions for operation of intelligent electric torque wrench

source:Industry News release time:2022-08-18 Article author:yu Popular:Air band saw

Intelligent electric torque wrenches have been used in all walks of life, and many people are familiar with them. However, some details are still very important. In the process of operation, we have more precautions.

Precautions for operation of intelligent electric torque wrench

1. The diameter of the bolt has a certain influence on the control accuracy. The same type of bolt connection should be used to calibrate the torque value during construction, and it should be checked and calibrated after a period of use.

2. The intelligent electric torque wrench should be turned on for 3-5 minutes before working. If it is found that the motor has large sparks, abnormal sound and unstable torque during operation, it should be stopped immediately for inspection, and do not work with illness.

3. The intelligent electric torque wrench should be cleaned and replaced regularly. Generally, after 5000 times of work, it should be cleaned and refueled once to prolong the service life. 4. The power switch on the main unit, the carbon brush, and the fuse on the controller are all vulnerable parts, which are easy to cause failure, and should be checked frequently and replaced in time.

5. If the screw on the tool is found to be loose during the use of the intelligent electric torque wrench, it should be tightened in time.

6. When carrying the tool, do not lift the cable, and pay attention to handle it with care to prevent vibration and falling. It should be placed in a ventilated and dry place when not in use. If it is found to be damp, it should be dried in time. It should not be in contact with or stored together with harmful substances such as acid and alkali.

Read recommendations:

CB22-310 Pneumatic Band Saw - Stainless Steel Series

CC21-250 Pneumatic Chainsaw (1.0KW Series)

Carbide Hollow Rail Drill Bits丨DM822 Series

Imported hydraulic wrench pump pressure should be stable.hydraulic impact wrench price

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

CS21-085 Pneumatic Handheld Circular Saw

2021-06-08AN31-180000 Hydraulic Torque Wrench

2023-06-27LW21-025 Pneumatic Winch

2023-06-29DM11-120 Electric Magnetic Drill

2023-06-19AK21-030 Pneumatic C-Hog Ring Plier (1.5 coil)

2022-12-12AN22-3500 Pneumatic Torque Wrench (Straight Shaft)

2023-06-27AN31-26000 Hydraulic Torque Wrench

2023-06-27AK22-110 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29LH22-010 Pneumatic Hoist

2023-06-29CN22-4150 Nut Cutter丨Split-type Nut Cutter

2023-06-17AN51-8000 Electric servo CNC Torque Wrench

2023-06-27AN21-550 Pneumatic Nut Runner

2020-06-13DA31-032 Hydraulic Angle Drill

2022-12-15AN32-40000 Hollow Hydraulic Wrench

2023-06-27RH31-1400 Hydraulic Chipping Hammer

2023-06-27GP21-004 Pneumatic Submersible Pump

2022-12-29RH21-1450 Pneumatic Chipping Hammer

2021-06-16AK22-130 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29DP21-080 Pneumatic Two Hand Operation Drill

2021-06-15CS21-180 Pneumatic Handheld Circular Saw

2020-06-13CC21-430 Pneumatic Chainsaw (3.0 kw Series)

2023-06-14OF27-200 Heavy Fixed Fan

2023-06-28LH22-002 Pneumatic Hoist

2023-06-29GG21-230 Pneumatic Angel Grinder

2021-06-15CF21-025 Pneumatic Cutter

2022-12-12GG11-178 Electric Angle Grinder

2022-12-28DM22-023 Pneumatic Rail Drill

2023-06-19OF23-880 Pneumatic Fan/ (light/medium)

2023-06-28DP21-060 Pneumatic Two Hand Operation Drill

2021-06-15AN11-4500 Electric servo CNC Torque Wrench

2023-06-27Accessories

Alloy Drill Bits丨812 Series

2023-06-06Ex-proof Sleeves

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Integrated Hollow Drill Bits丨DC81

2023-06-07Regular Saw Chains丨CC811 Series

2023-06-06Platform Clamps丨CB863-19

2023-06-06Alloy Saw Blades

2023-06-06Chisels

2023-06-07Rail Clamps丨CB864-12

2023-06-06Cross Clamps丨CB862-22

2023-06-06Hydraulic Regulating Valve

2023-06-07Alloy Saw Blades丨CR816 Series

2023-06-06Tool Bits

2023-06-07Tool Bits

2023-06-07Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Alloy Sleeves

2023-06-07Cutting Blades

2023-06-07Optional Accessories

2023-06-07Abrasive Blades

2023-06-07Non-metallic Alloy Saw Blades

2023-06-06Diamond Saw Blades

2023-06-06Core Drill Morse Taper Sleeves

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Alloy Saw Blades丨CR811-150/152

2023-06-06Oiler

2020-06-13Shovel Blades

2023-06-07Alloy Saw Blades丨CR811 Series

2023-06-06Pipe Fixed Clamps丨CB861-12

2023-06-06Carbide Hollow Bits丨DM818 Series

2023-06-06

You are here: >

You are here: >