- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

How to use hydraulic wrench.Air impact wrench

source:Industry News release time:2022-04-26 Article author:yu Popular:Air band saw

1. First, prepare No. 32 or No. 46 anti-wear hydraulic oil (depending on the temperature and region), and after preparing the hydraulic oil, you can start to fill the oil cylinder of the hydraulic wrench pump station with oil (pay attention to remind the oil inlet hole of the electric pump, The position of the oil outlet, the level gauge and the pressure regulating valve), pay attention to the level gauge when filling oil, when the level gauge shows 3/4, you can stop pouring oil. Note: If the oil is not new, then it needs to be filtered with a filter screen to prevent debris or impurities from entering the oil cylinder; the thermometer in the liquid level gauge is an oil temperature gauge; the anti-wear hydraulic oil in the oil cylinder is best if used frequently 1- Change it every 2 weeks, or every 1-2 months if you don't use it frequently.

2. The next step is the hydraulic wrench oil pipe. When connecting the oil pipe, pay attention to the connection of the quick connector must be tightly locked and locked, and there must be no gap after locking. Only in this way can the connection be ensured, so that the check valve in the joint is opened and the oil circuit is unblocked. Otherwise, after the connection, the steel balls in the joint will not meet, and the one-way valve in the joint cannot be opened, resulting in the blockage of the oil circuit, the joint will be full of pressure, and the wrench will not be able to operate. The second is to avoid excessive bending of the oil pipe when connecting the pump station, the oil pipe and the wrench, and use it as straight as possible.

3. Connect the hydraulic wrench pump station to the 220V power supply, check the tightness of the pressure regulating valve before turning on the pump station switch, and loosen the pressure regulating valve to avoid starting with pressure. The red key on the remote control handle of the pump station is the power-off key, and the green key is the power-on and oil-in key. When a new pump station or a pump station after oil change is started, it is necessary to switch the motor on and off 3-4 times and idle for a period of time to remove the air in the fuel tank. Then turn on the switch, press and hold the oil input button, and slowly and uniformly tighten the pressure regulating valve to the required pressure (MPa). After adjusting the pressure, you can start to use the wrench.

4. Before use, determine whether the bolts are tightened or disassembled, and change the direction of the drive shaft according to the needs of the site. Press and hold the circular button in the middle of the locker and pull the drive shaft lightly to disengage the drive shaft from the locker, and the drive shaft can be pulled out. After confirming the direction, put the drive shaft out of the wrench, make it fully engage with the spline sleeve, and then tighten the lock.

5. When using the hydraulic wrench, press and hold the oil input button, the oil pipe will start to enter the oil, and the drive shaft will start to rotate. When you hear the sound of the wrench clicking, it proves that the oil input is completed and then release the oil input button, and the wrench will start to return. After a period of time, the sound of the wrench clicking proves that the oil return is complete. (Note: Be sure to press the oil input button to start oil feeding after the oil return is completed, if the oil return is not successful.)

6. The square shaft starts to rotate, the wrench stops rotating in place, the pressure gauge rises rapidly from "0" to the set pressure; release the button, the wrench automatically returns, repeat several times, make the wrench idling for several times, observe the wrench's rotation, To determine whether to loosen or lock the operation, only put the wrench on the socket when there is no abnormality.

Read recommendations:

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

CD22-250 Pneumatic Concrete Chainsaw (5.0KW)

2020-06-13DP61-140 Emulsion Two Hand Operation Drill

2023-06-19GP21-060 Pneumatic Submersible Pump

2022-12-29CB31-260 Hydraulic Band Saw

2023-06-16DM11-080 Electric Magnetic Drill

2023-06-19AN31-1800 Hydraulic Torque Wrench

2022-12-27AN11-6000 Electric servo CNC Torque Wrench

2023-06-27DC21-100 Pneumatic Core Drill

2023-06-20DM21-030 Pneumatic Magnetic Drill

2020-06-13DM11-050 Electric Magnetic Drill

2023-06-19DH21-016 Pneumatic Hammer Drill

2020-06-13DC11-100 Electric Core Drill

2023-01-03CC20-380 Pneumatic Chainsaw

2020-06-13DB21-060 Pneumatic Rotary Drill Heavy Duty

2023-06-19LH21 Series Pneumatic Hoist

2023-05-11CB61-160丨Emulsion Band Saw

2023-06-17OW63-020 Integrated Emulsion Mining Waterjet Cutting Machine

2023-05-10AN11-8000 Electric servo CNC Torque Wrench

2023-06-27DB21-020 Pneumatic Rotary Drill Heavy Duty

2023-06-19LH22-003 Pneumatic Hoist

2023-05-11AN71-15000 Torque Multiplier

2023-06-29CC21-530 Pneumatic Light Chainsaw (3.0 kw Series)

2023-06-14GA21-125 Pneumatic Wet Grinder

2023-06-28AN31-20000 Hydraulic Torque Wrench

2023-06-27CR21-012 Heavy Pneumatic Reciprocating Saw

2021-06-07DC31-300 Hydraulic Core Drill

2023-06-20CN22-70115 Nut Cutter丨Split-type Nut Cutter

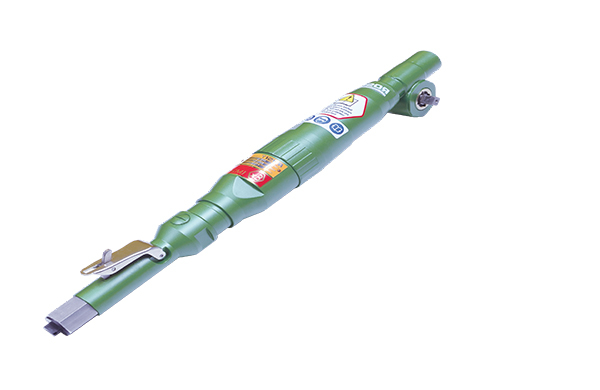

2022-12-12AN23-750 Pneumatic Torque Wrench (Angle Shank)

2024-03-12CB22-310 Pneumatic Band Saw - Stainless Steel Series

2023-06-16CB61-200丨Emulsion Band Saw

2023-06-17Accessories

Clamps

2023-06-06Hydraulic Regulating Valve

2023-06-07Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Drill Bit Extension Rods丨DC88 Series

2023-06-07Diamond Saw Blades

2023-06-06Rail Clamps丨CB864-12

2023-06-06Alloy Saw Blades丨CR815 Series

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Alloy Drill Bits丨811 Series

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Pipe Fixed Clamps丨CB861-18

2023-06-06Tool Bits

2023-06-07Grinding Disc

2023-06-07Alloy Sleeves

2023-06-07Alloy Guide Bars丨CC814 Series

2023-06-06Water Pump

2020-06-13Abrasive Blades

2023-06-07Filter assy.

2023-06-07Platform Clamps丨CB863-19

2023-06-06Chisels

2023-06-07Pipe Fixed Clamps丨CB861-12

2023-06-06Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Alloy Saw Blades丨CR816 Series

2023-06-06Filter assy.

2023-06-07Cross Clamps丨CB862-22

2023-06-06Sleeve KIT

2023-06-07Alloy Saw Blades

2023-06-06Alloy Saw Blades

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06

You are here: >

You are here: >