- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

The precautions for hollow hydraulic wrench are as follows:Air hoist Vendor

source:Industry News release time:2022-03-23 Article author:Rosit Popular:Air band saw

Precautions for the use of hollow hydraulic wrench

Hollow hydraulic wrench is a kind of hydraulic wrench, and it is also one of the main sales of Quecher Hydraulic. This product has a wide range of applications. The hollow hydraulic wrench is thin in thickness and is especially suitable for places where the space is relatively narrow, so it is used in many industries and is also very practical. There are also many points of attention in the operation of hollow hydraulic wrenches.

The precautions for hollow hydraulic wrench are as follows:

1. In order to avoid personal injury and possible equipment damage, ensure that each hydraulic component can withstand a working pressure of 70MPa (700bar) In order to avoid personal injury and possible equipment damage, ensure that each hydraulic component can withstand 70MPa (700bar) work pressure.

2. Do not exceed the rated load of the equipment Minimize the risk of overloading; use a pressure gauge in the system to display the operating load. The pressure gauge is a window into what's going on within the system. When using a hydraulic wrench, do not exceed its maximum allowable value.

3. Avoid damaging the hydraulic oil pipe Serious bending and winding of the hydraulic oil pipe should be avoided during use. Using bent or twisted tubing will create excessive back pressure. Severe bends and tangles cause internal damage to the tubing, resulting in premature failure. Do not drop or press heavy objects onto the tubing. Severe impact can cause damage to the metal wire inside the oil pipe, and the damaged oil pipe may rupture when pressurized.

Correct operation steps can improve the service life of hollow hydraulic wrench:

1. Install the hydraulic wrench and tighten the oil return valve rod clockwise before use

2. The working oil of the hydraulic puller is preferably anti-wear hydraulic oil, and the working oil must be clean.

3. According to the size of the preload nut, select the inner hexagon socket.

4. Insert the high-pressure and low-pressure hoses with quick connectors into the connection between the wrench and the reversing valve

5. Tilt the piston starting rod back and forth to move forward steadily, and the claw hook retreats accordingly to pull out the object to be pulled.

6. The angle of the connecting rod of the wrench should be controlled within the range of the angle calibrated by the reaction rod.

7. Suppression

9. After removing the quick connector, the exposed part of the connector must be covered with a plastic cover;

Read recommendations:

DM31-030 Hydraulic Magnetic Drill

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

CB22-160 Pneumatic Band Saw - Stainless Steel Series

2023-06-16CB21-065 Pneumatic Band Saw - Aluminum Alloy Series

2021-06-07AN32-40000 Hollow Hydraulic Wrench

2023-06-27CR21-010 Heavy Pneumatic receprocating Saw

2021-06-07LH31 Series Hydraulic Hoist

2023-05-11DP21-100 Pneumatic Two Hand Operation Drill

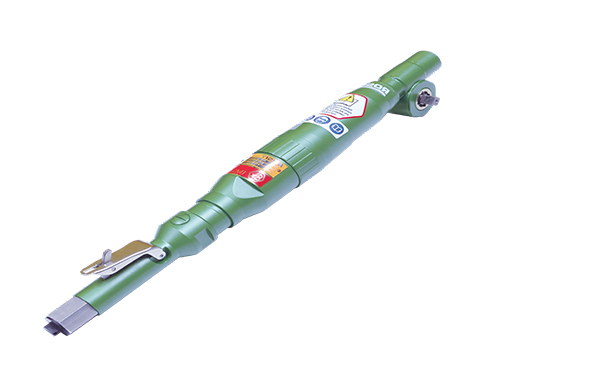

2023-06-19AN22-4500 Pneumatic Torque Wrench (straight shaft)

2023-06-27RZ21-014 Pneumatic Rammer

2022-12-28LH12 Series Chain Hoist

2023-05-11GP21-030 Pneumatic Submersible Pump

2022-12-29OF22-880 Pneumatic Fan (light/medium)

2023-06-28DB21-050 Pneumatic Rotary Drill Heavy Duty

2023-06-19CR21-003 Light Pneumatic Reciprocating Saw

2021-06-07AN31-120000 Hydraulic Torque Wrench

2023-06-27DA21-050 Pneumatic Angle Drill

2023-06-19LH22-010 Pneumatic Hoist

2023-06-29AW22-1200 Pneumatic Impact Wrench (Ultra-Light Series)

2022-12-20DM31-035 Hydraulic Magnetic Drill

2022-12-30CB22-200 Pneumatic Band Saw - Stainless Steel Series

2023-06-16RH21-230 Pneumatic Chipping Hammer

2021-06-16DM31-030 Hydraulic Magnetic Drill

2020-06-13CR21-005 Light Pneumatic Reciprocating Saw

2021-06-07CB21-120 Pneumatic Band Saw - Aluminum Alloy Series

2023-01-06AK22-080 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29CB61-160丨Emulsion Band Saw

2023-06-17DM11-080 Electric Magnetic Drill

2023-06-19GG21-230 Pneumatic Angel Grinder

2021-06-15RH31-1550 Hydraulic Chipping Hammer

2023-06-27CB11-160 Electric Band Saw

2023-06-16DM21-045 Pneumatic Magnetic Drill

2022-12-15Accessories

Split Hollow Drill Bits丨DC82

2023-06-07Pipe Fixed Clamps丨CB861-18

2023-06-06Clamps

2023-06-06Drill Bit Extension Rods丨DC88 Series

2023-06-07Pin

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Filter assy.

2023-06-07Alloy Drill Bits丨813 Series

2023-06-06Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Tool Bits

2023-06-07Platform Clamps丨CB863-19

2023-06-06Alloy Saw Blades丨CR812 Series

2023-06-06Integrated Hollow Drill Bits丨DC81

2023-06-07Diamond Saw Chains

2020-06-13Chisels

2023-06-07Optional Accessories

2023-06-07Alloy Saw Blades丨CR811-150/152

2023-06-06Alloy Saw Blades丨CR814 Series

2023-06-06Carbide Hollow Bits丨DM818 Series

2023-06-06Shovel Blades

2023-06-07Alloy Saw Chains丨CC812/CC816 Series

2023-06-06Water Pump

2020-06-13Core Drill Morse Taper Sleeves

2023-06-07Alloy Saw Blades

2023-06-06Ex-proof Sleeves KIT

2023-06-07Alloy Saw Blades丨CR816 Series

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06Alloy Sleeves

2023-06-07Ex-proof Sleeves

2023-06-07Sleeve KIT

2023-06-07

You are here: >

You are here: >